What is the StepUp modular bed system, and how does it work?

StepUp is a modular, elevated bed system designed to make upper sleeping areas safer and more accessible. Each unit includes a built-in step platform that eliminates the need for ladders, making it easier for guests of all ages and abilities to reach their sleeping space. The system is engineered to be durable, comfortable, and easy to maintain in high-density living environments.

Who is StepUp designed for, and what types of facilities benefit from it most?

StepUp is built for any organization that offers shared sleeping accommodations. This includes shelters, transitional housing programs, emergency response centers, student housing, camps, and other facilities where maximizing space while ensuring dignity and comfort is essential. It supports both short-term and long-term residents.

Are there different StepUp modular bed system designs?

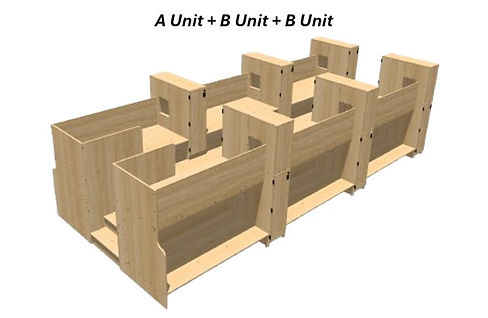

Yes, there are. The flagship StepUp Bed modular system is built around two core units: the A Unit, which includes four beds and integrated stairs, and the B Unit, which also includes four beds and is designed to adjoin seamlessly to an A Unit.

An A Unit can be used on its own or can be seamlessly adjoin to a B Unit.

Up to two B Units can be added to a single A Unit, or two A Units can be bookended onto two B Units, allowing for stairs on both ends. StepUp is designed to be a flexible and scalable sleeping solution for high-density or community-based environments.

Additionally, a StepUp bunk bed, and stand alone wardrobe is currently in development.

Can StepUp be customized for different room layouts or population sizes?

Yes. StepUp’s modular system can be arranged in numerous configurations to fit a wide range of room shapes and sizes. Our team can help design a layout optimized for your space, capacity goals, and operational needs. Custom accessories and options are also available to further tailor the system.

Is StepUp easy to install or reconfigure as needs change?

StepUp is designed with simplicity and flexibility in mind. Each A or B unit can be assembled in approximately 60–90 minutes by three people using a drill/driver and basic hand tools. At least three people are recommended due to the size and weight of some panels. Customers with larger installations often organize build days with volunteer support to speed up the assembly process.

The modular design allows facilities to reconfigure layouts as populations, room sizes, or operational needs change, making StepUp a reliable solution for evolving environments. While StepUp beds can be disassembled and reassembled, their design is best suited for long-term placement.

What safety features does StepUp include for guests using upper sleeping areas?

Safety is at the core of StepUp's design. Each StepUp A Unit includes a stable built-in step system, ADA compliant handrail for secure climbing, and a wide entry point to the top bunk. The structure itself is made from robust Baltic Birch material engineered for long-term, high-use environments. The design reduces fall risk and provides more confidence for guests who may struggle with ladders or mobility issues.

Do StepUp beds help reduce the risk or spread of bed bugs?

Yes, StepUp beds are designed with features that support effective bed bug mitigation, but the most important factor in controlling bed bugs is a proactive treatment and inspection program with your local pest control provider. Regular quarterly inspections help identify small issues early—long before they become infestations.

From a design standpoint, StepUp beds intentionally make pest control easier and more effective. The stairs can be pulled away, and the units include specific cutouts so pest control teams can easily spray hard-to-reach areas. The beds are built from furniture-grade Baltic Birch, which is non-porous, and has no natural cracks or crevices where bed bugs can hide. A polyurethane coating prevents bugs from getting into the wood itself, and provides an easy and fast wipe down surface.

As with any metal or wood bed, the key risk area is the seams—so every StepUp unit is fully caulked at all seams after assembly, creating a sealed barrier. Pest control professionals we’ve consulted with have emphasized that this caulking strategy is critical in reducing potential hiding places.

Together, these design choices support better prevention and easier treatment as part of your regular pest control program.

Does StepUp comply with shelter or housing safety regulations?

Yes. StepUp is engineered to meet or exceed the safety and durability standards required by shelters, housing programs, and other high-density facilities. StepUp was created in partnership with the Everett Gospel Mission to address shortcomings in their own facility, and as of December 2025, StepUp beds have been installed in more than 16 facilities across the United States.

Because each municipality has its own building regulations, proper due diligence should be completed prior to installation. StepUp is available to assist with this process.